Structural Engineering Laboratory

Division of Structural Engineering

The Structural Engineering Lab is part of the Civil Engineering Laboratory at LTH which can be found via LTH Open Door. The Structural Engineering lab can provide equipment and expertise in mechanical testing and environmental testing of various materials, including static, quasi-static and fatigue testing. Environmental testing includes e.g. moisture content and material climate monitoring, driving rain testing etc.

In-house expertise

At Structural Engineering we have a long tradition of studying wood and wood-based materials, concrete and masonry. Typical topics include testing of material strength and stiffness, load bearing capacity of components and joints as well as instability testing.

User skill requirements

A basic knowledge of how to use the equipment is expected, but not mandatory. A brief introduction to the equipment is included. Staff members are available for assistance depending on your specific requirements. Some of the equipment needs to be operated by our staff.

Equipment

The laboratory has access to advanced measuring equipment such as a servo hydraulic test machine (e.g. tensile, compression, shear or bending tests), load cells and deformation measurement equipment. We also have a climate chamber (1m3), access to climate rooms and an outdoor test facility along with a workshop for preparation of wooden components.

The Division of Structural Engineering has a test hall with a total area of approximately 680 square metres. The test hall has a tensioned floor and a clear ceiling height of approximately 6 metres, and there is also an area of approximately 480 square metres with a clear ceiling height of approximately 9 metres. There are also two 10-tonne cranes and an electric forklift.

Structural Engineering's testing machines consist of an MTS (Measure Test Simulate) test rig, a servo-hydraulic testing machine (Photo 1), and an older MAN (Maschinenfabrik Augsburg-Nürnberg) hydraulic testing machine. The latter has been modernised and, like the MTS machine, is computer-controlled (Photo 2).

In addition, there are two loose servo-hydraulic pistons. These pistons also have a test rig that can be adapted to different types of tests (Photo 3).

Hydraulic pistons

The Division also has a number of manual hydraulic pistons and jacks that can be used for simple static tests. These have a capacity of 100 and 200 kN (KiloNewton) respectively. There is also a smaller test rig that can handle a load of 100 kN (KiloNewton) to mount these pistons in (Photo 4).

Load cells

The laboratory has a large number of load cells available, currently about 30. Many load cells are capable of measuring both compressive and tensile forces. The capacity varies between 0.5 kN and 2000 kN. Some of the load cells can withstand extreme climatic conditions (Photo 5).

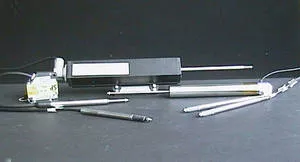

Deformation sensors

The available strain gauges are resistive and inductive. The measuring ranges vary between 5 and 200 millimetres. Some of the inductive sensors are also climate-resistant (Photo 6).

Peripherals

There is also a CTS climate chamber in the Structural Engineering Laboratory. The chamber has a volume of about 1 cubic metre, is computer-controlled and can withstand -40 to 180 °C and 10 to 98 % relative humidity (Photo 7).

There are also measuring instruments for determining dynamic E-modulus (Grindosonic)

In addition, there is digital photography equipment for still photography and video recording of the tests performed.

Typical customers/users

Companies and researchers who want to measure mechanical properties such as strength, stiffness, load bearing capacity of materials and elements, connections or look at moisture/temperature effects.

Fees

Information about the lab fees and lab access is available upon request, depending on the equipment and assistance needed and duration of the testing.

Insurance and safety

The instruments in our lab are very sensitive and expensive, therefore we expect users to have their own insurance. All users must sign a safety and security agreement before entering our premises and using the equipment.

Contact

Martin Gunder

Lab technician

martin [dot] gunder [at] kstr [dot] lth [dot] se (martin[dot]gunder[at]kstr[dot]lth[dot]se)

+46 46 222 95 05

Email lab: kstrlabb [at] epic [dot] lu [dot] se (kstrlabb[at]epic[dot]lu[dot]se)